Copper IMS & Heatsink Technology - Metal Plate PCB

The Optimal Solutions for Heat Dissipation of Electronic Systems

The increasing power density of electronic components, ever more compact sizes of electronic assemblies and higher temperature requirements generally result in increased heat production by the individual assemblies.

With maximum reliability and service life of the assemblies in mind, the heat produced needs to be dissipated in order to reliably prevent critical temperatures and to operate the assembly under all environmental conditions within the admissible temperature limits.

One extremely efficient way of dissipating heat from an electronic assembly is to conduct the heat from its source through the printed circuit board to a defined heatsink. This heatsink, in turn, can be part of the housing concept.

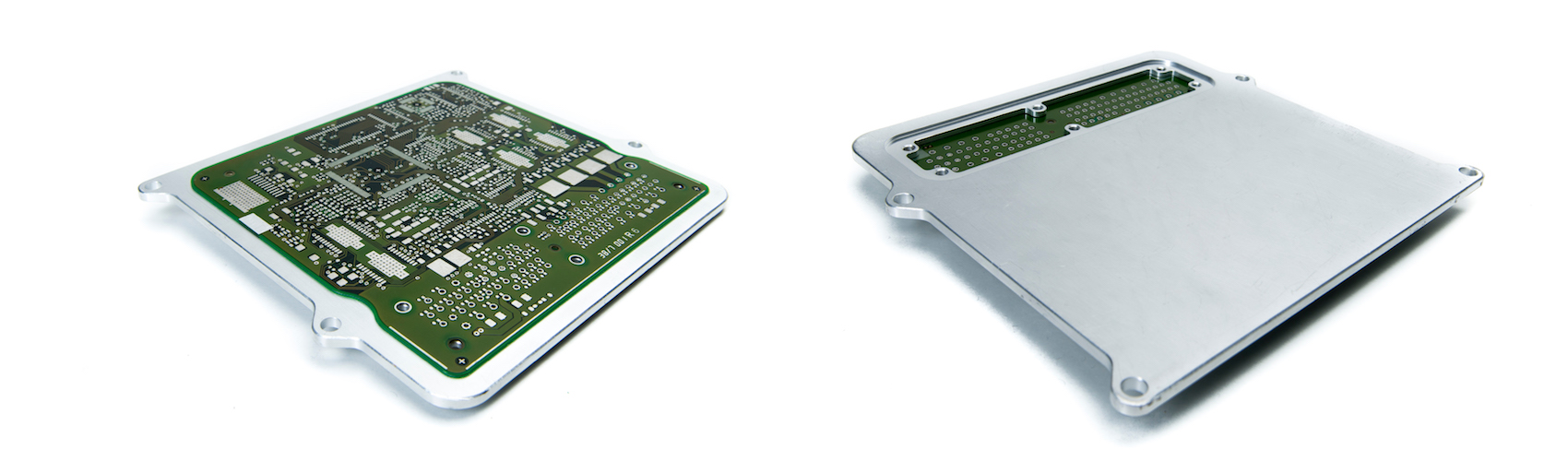

Unimicron Germany offers heatsink technology under the product designation Metal Plate. In this technology heatsinks in the form of sheet metal (preferably copper or aluminium) are applied on the printed circuit board for better heat dissipation / distribution.

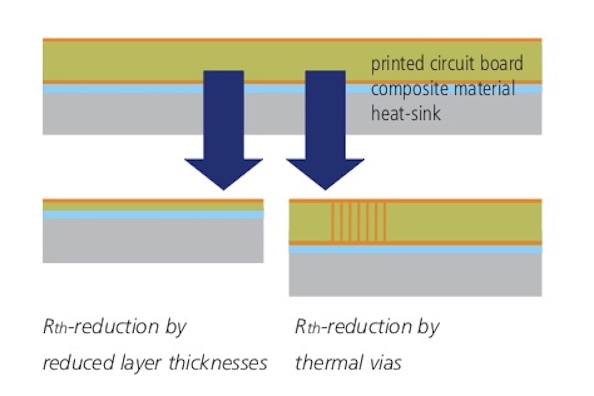

The thermal resistance (Rth) can be reduced by thin layers - thin printed circuit boards - or alternatively by copper paths through the PCB, such as for example thermal vias or Metal Inlay.

The heatsink is normally connected to the printed circuit board by temperature-resistant pressure-sensitive adhesive films. Other composites (e.g. prepreg) are also possible.

Applications:

- e-mobility and automotive

- industrial electronics

- lightning technology

Advantages:

- optimal heat dissipation

- high reliability

- combination with all technologies possible

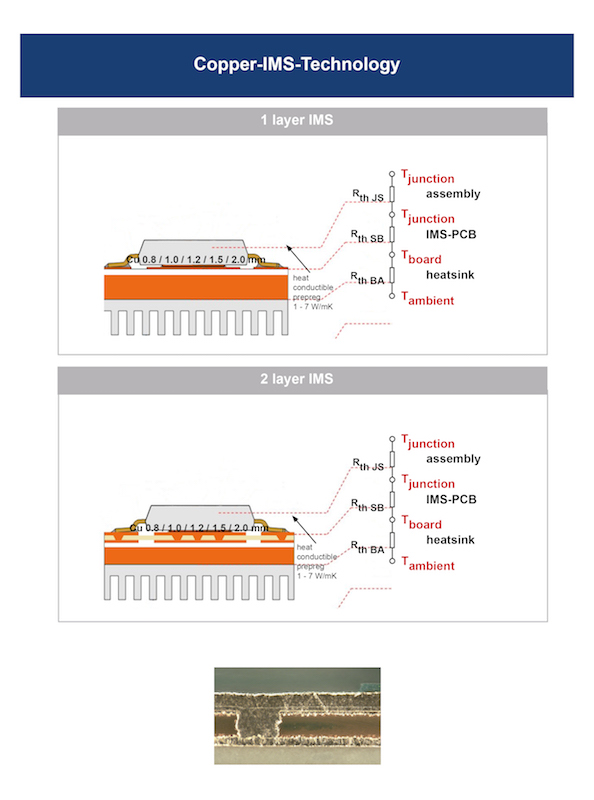

Example of a 1- and 2-layer build up of copper-IMS

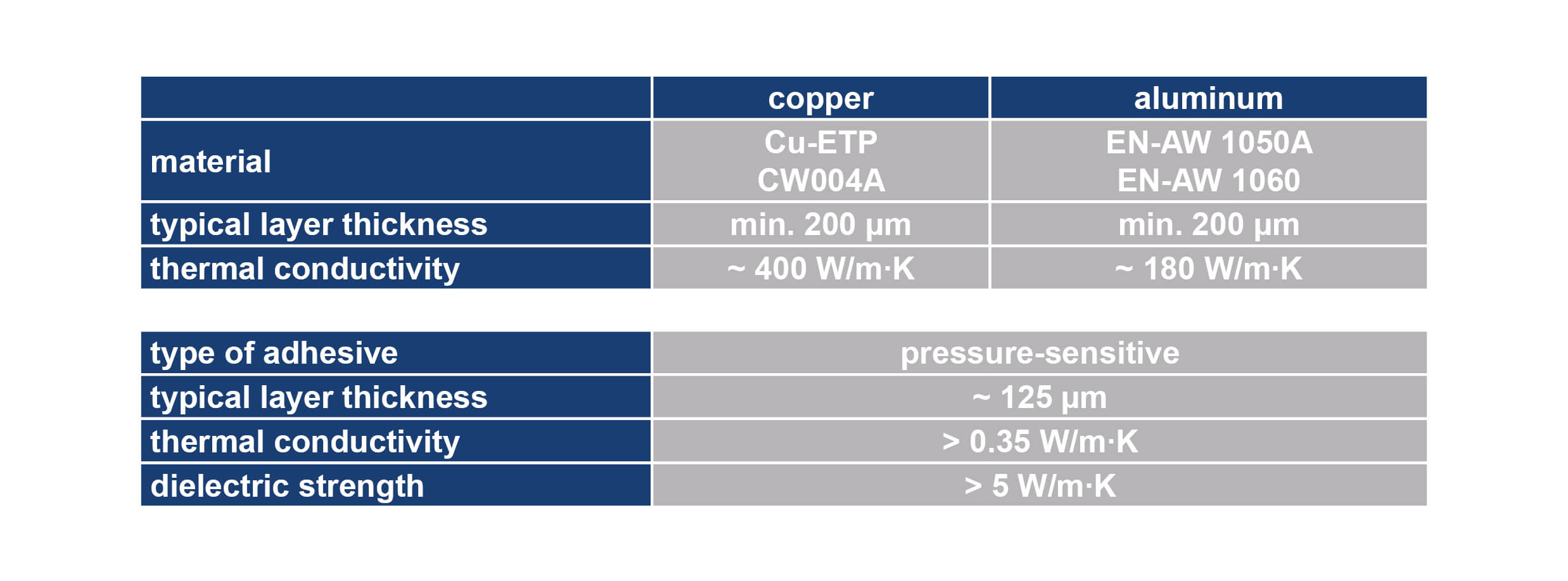

Base Materials

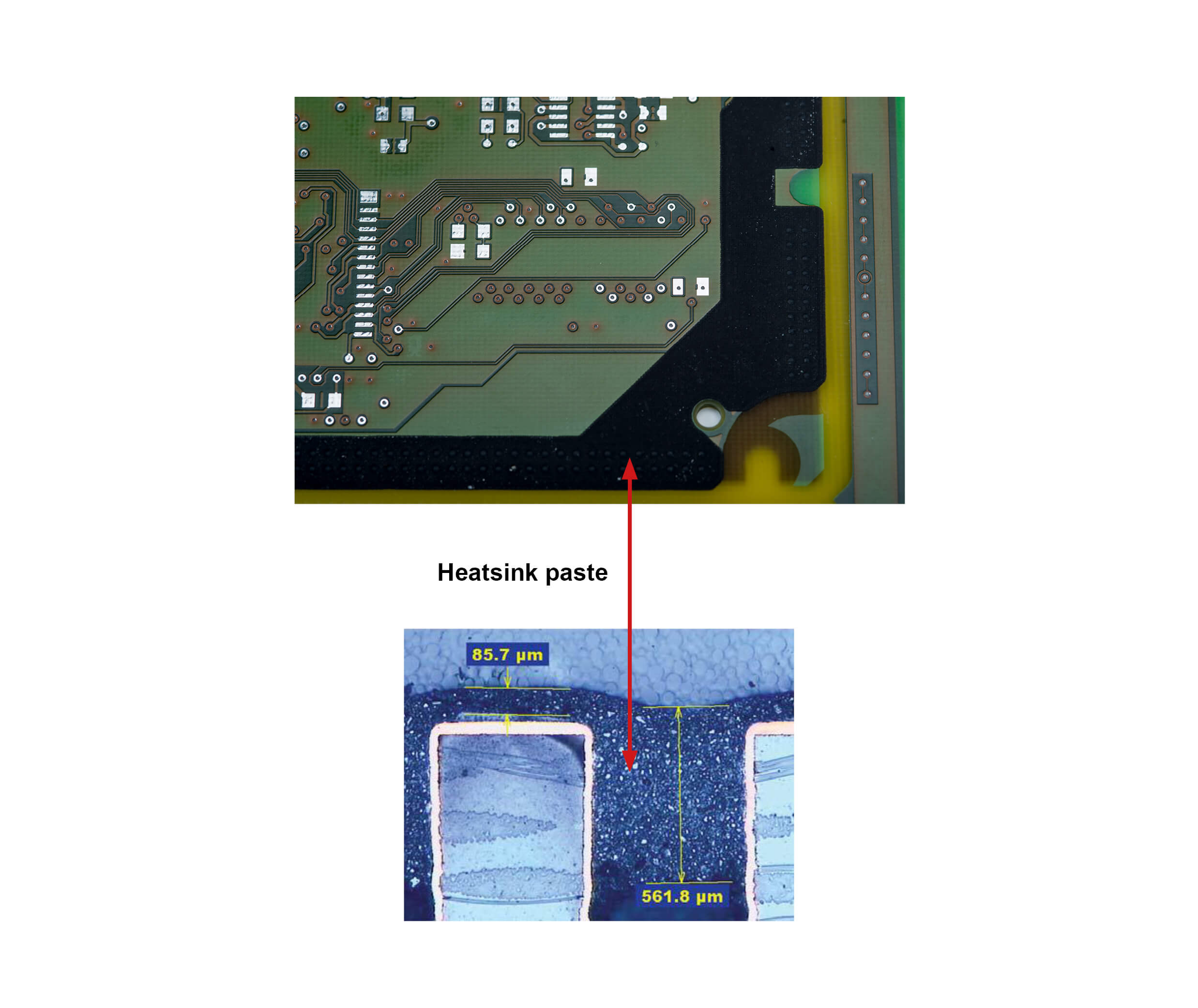

Heatsink Paste as an Alternative for a Metal Plate:

A possible alternative to Metal Plate PCB is the printing of a heatsink paste.

For this we use two different heatsink pastes, which conduct heat but no current.

Parameters of the Paste:

- thermal conductivity: λ = 2 Wm·K

- dielectric strength: 10 kVmm

- TG = 65°C

- colour black

- density: 2.05 ± 0.05 gcm3

Contact to product management:

product management

+49 (0) 2831 - 3 94-0

info@unimicron.de

Further PCB Technologies:

Thick Copper Technology - HiCu PCB | Thick Copper Profile Technology - HiCu Profile PCB | HDI Technology - HiDensity PCB | High Frequency Technology - HiFrequency PCB | Metal Inlay Technology - Metal Inlay PCB | Semiflex Technology - Semiflex PCB | Partial Thick Copper Technology - Wirelaid®